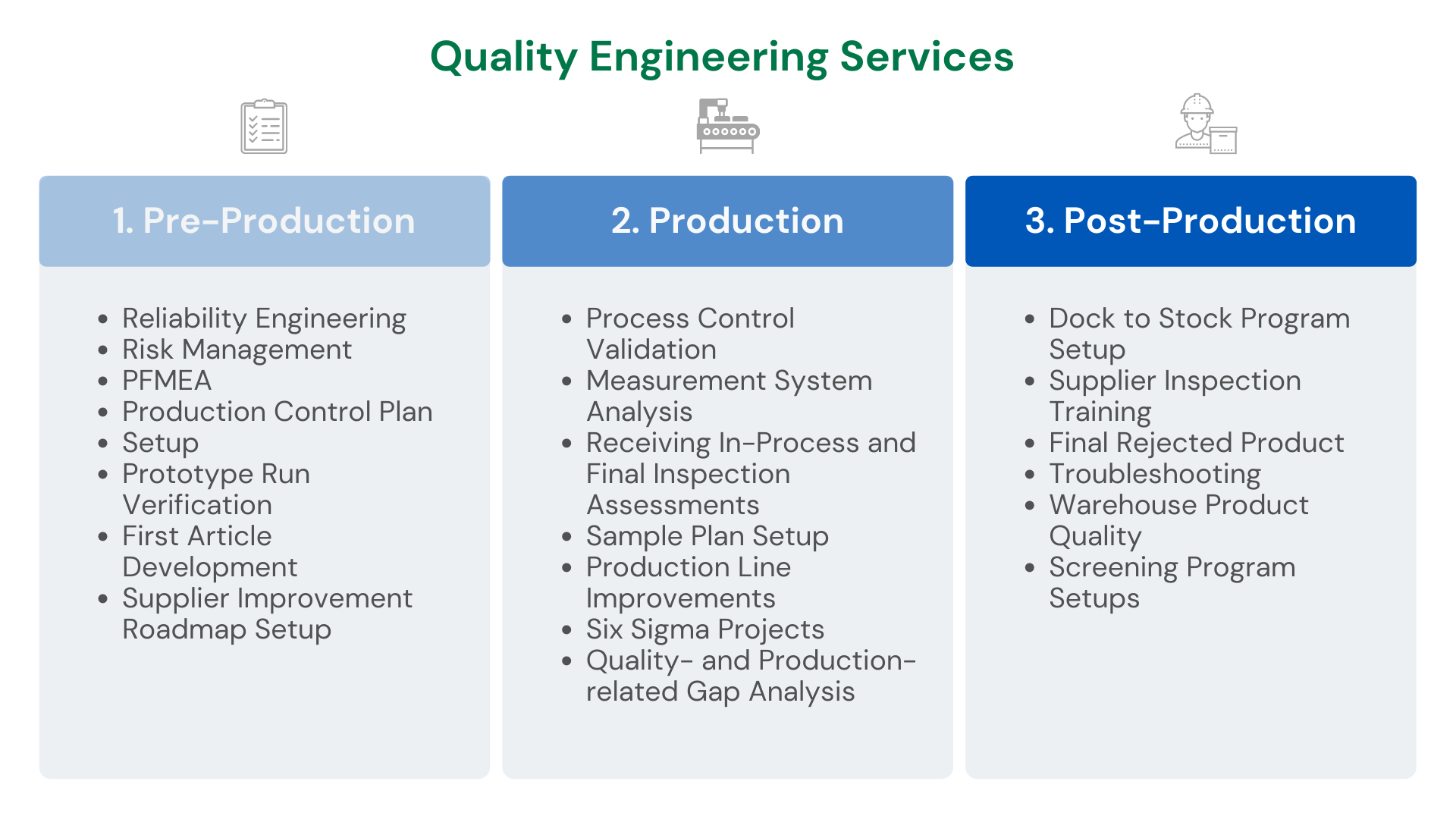

Our Quality Engineering services provide technical leadership and support in pre-, mid-, and post-production environments at any point in the global supply chain.

Our seasoned, specialized quality engineers are typically deployed as part of a larger managed program. This ensures full alignment with client strategy and goals for supplier quality – not just the activity at hand. We can provide full Quality Engineering services through the entire manufacturing life cycle. Capabilities include:

Pre-Production

- Reliability Engineering

- Risk Management

- PFMEA

- First Article Inspection Program Development

Production

- Process Control Validation

- Measurement Systems Analysis

- In-process and Final Inspection Program Development

- Production Line Improvement

Post-Production

- Dock-to-Stock Program Development

- Supplier Inspection Training

- Root Cause Analysis

- Quality- and Production-related Gap Analysis

Key Benefits

- located in hundreds of cities throughout the US and in over 50 industrialized foreign countries

- industry experts to suit your needs

- short- or long-term availability

- global presence, local position

- fully supported by SQA’s Engineering, IT, and administrative program management resources

Getting Started

We typically begin a long and successful client relationship by satisfying a single, challenging requirement for expert Engineering support. Feel free to talk to a Sales Representative or Project Manager about your needs, without obligation. All we need to get started is your:

- Specific technical requirements

- Geographic area and time frames

- A purchase order or signed contract

… and SQA’s service team will provide you with a variety of suitable support options in the shortest possible time.

Comments are closed.